NT Build 492 is a test that determines the diffusion coefficient of concrete. Diffusion is the movement of a dissolved substance under a concentration gradient. That is, ions in solution move from areas of high concentration to areas of lower concentration. That’s important because concrete durability is all about keeping harmful substances out. The ion of interest is most often chloride that migrates into the concrete from road salts or seawater. When enough chloride reaches the reinforcing steel, corrosion begins. It’s corrosion that most often limits the service life of reinforced concrete.

Chloride ions act as catalysts for the corrosion of steel. For this reason, it’s important to know how quickly they can move through concrete. You can design concretes to resist chloride diffusion and use NT Build 492 to compare their performance.

NT Build 492

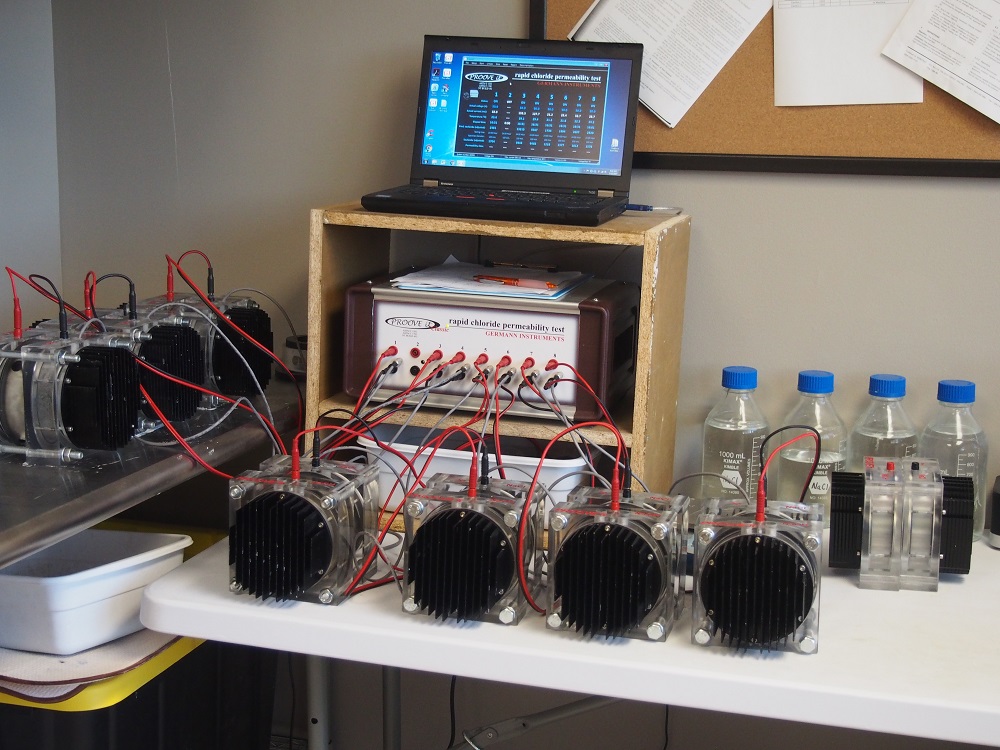

Two-in.-thick slices of 4-in.-diameter concrete cylinders are conditioned, then placed in cells with a solution of sodium hydroxide (NaOH) on one side and a solution of sodium chloride (NaCl) on the other. An electrical potential of 30 V drives the chlorides into the concrete.

After 24 to 96 hours, the concrete sample is split open. An indicator solution of silver nitrate (AgNO3) sprayed onto the broken surface shows where the chlorides have penetrated. The white silver chloride (AgCl) precipitate is readily visible on the broken surface. The depth of penetration is used to calculate the diffusion coefficient.

The test equipment is similar to that used for the more well-known Rapid Chloride Permeability test, ASTM 1202, which takes about two days to complete after 28 days of standard curing. ASTM C1202 reports how much electric charge passes through a concrete sample in a set length of time. That value correlates to a subjective value of permeability: High, Medium, Low, Very Low. By contrast, NT Build 492 measures a non-steady state diffusion coefficient.

In comparison with ASTM C 1556, the NT Build 492 diffusion coefficient will be slightly higher–that is, less favorable. However, NT Build 492 gives a result in 2 to 5 days after the 28-day curing of the concrete. On the other hand, ASTM C1556 takes anywhere from 50 to 65 days to complete and typically costs more, too.

Predicting service life

Programs such as Life-365 predict the service life of concrete based on how long it takes chloride ions to migrate in to the steel reinforcement. The diffusion coefficient of the concrete is a key input parameter in Life-365. The lower the diffusion coefficient, the slower the diffusion and the longer the service life.

In 2015, Beton partnered with the Minnesota Department of Transportation to investigate the effect of timing of thin polymer overlay applications on the service life of bridge decks. The research included testing the diffusion coefficients of new bridge decks. Some of these bridge decks had 20% Class F fly ash, while others had 100% portland cement. The total cementitious content ranged from 535 to 600 lbs/ yd3. The water-to-cement ratio was constant at 0.42. We used NT Build 492 to determine the diffusion coefficients. The results showed that substituting fly ash for 20% of the portland cement increased the service life of the bridge deck by 300%.

As you can see, NT Build 492 gives useful information relatively quickly so you can design more durable concrete. We can help you select the right tests for your project.