NT Build 492 yields an apparent diffusion coefficient that can be used to predict service life.

Like ASTM C1202, NT Build 492 is an electrical test in which the samples are exposed to solutions of NaCl and NaOH. However, the voltage is lower and the exposure time is a few days rather than 6 hours.

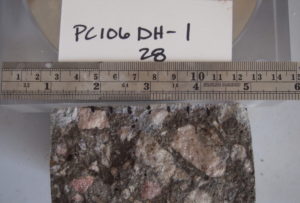

Once the exposure is completed, the sample is split in half and a silver nitrate solution is sprayed on the fractured surface. White silver nitrate precipitates where chloride ions are present. The diffusion coefficient is calculated from the chloride penetration, sample thickness, exposure time, voltage, and average sample temperature.

For new concrete, NT Build 492 is much faster than ASTM C1556 and gives similar results.

NT Build 492 takes slightly longer than ASTM C1202, but gives much more “granular” information. However, because it’s also an electrical test, the same limitations apply as far as the type of concrete. That is, don’t use it on concrete with steel fibers or corrosion inhibitor.