The widely specified “rapid chloride permeability” test is a proxy for corrosion resistance.

Corrosion of reinforcement is the most common reason for deterioration of concrete structures. Chloride ions from deicing salts or seawater act as catalysts for corrosion, so concrete needs to resist the ingress of chlorides. ASTM C1202 is a quick test of the resistance of concrete to chloride ingress.

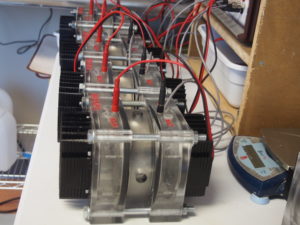

Concrete cylinders are cut in 2-in. slices. The cast surfaces are coated with waterproof epoxy. Then the samples are conditioned to saturate the cut surfaces. The samples are placed in test cells with NaOH solution on one side and NaCl solution on the other. A potential of 60 V is maintained across the sample for 6 hours. The total charge passed is used to rate the chloride ion penetrability:

- > 4000 coulombs: High

- 2000-4000 coulombs: Moderate

- 1000-2000 coulombs: Low

- 100-1000 coulombs: Very low

- < 100 coulombs: Negligible

ASTM C1202 is an indirect measure of resistance to chloride ion migration. Changes in the composition of the concrete pore solution may affect the electrical properties more than they affect chloride ion migration. Concrete samples with steel fibers or corrosion inhibitor are not suitable for testing by this method.