ASTM C1556 and NT Build 492 both measure the ease with which chloride ions migrate into concrete. Both test methods estimate the diffusion coefficient, a measure of the rate at which dissolved chlorides migrate in concrete under a concentration gradient. You can use either estimate of the diffusion coefficient in a program such as Life-365 to predict the service life of a concrete structure. So what’s the difference?

ASTM C1556

Chloride ions act as catalysts for the corrosion of steel. Corrosion is often what limits the service life of concrete structures. For this reason, it’s important to know how quickly chlorides can move through concrete.

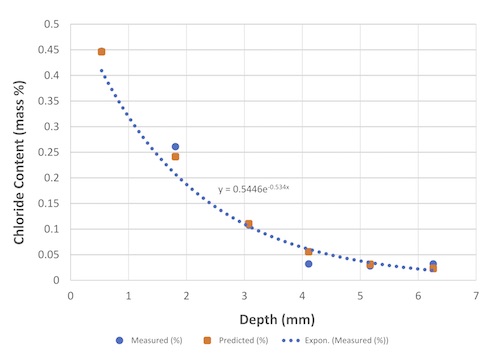

ASTM C1556 produces a chloride concentration profile like the one shown here. Starting from the top surface, the technician samples the concrete at 1-mm to 15-mm intervals and obtains the chloride concentration of each. From the plot of concentration versus distance from surface, linear regression gives a best-fit curve for the data. The equation of the curve tells us what the apparent diffusion coefficient is.

If you’re evaluating a proposed concrete for a new project, you’ll need 2 to 3 months to complete the test. Cast cylinders of the concrete and cure them for 28 days. Then seal the bottom and sides. Soak the cylinder in a salt solution for 35 days, then mill off layers of the concrete to analyze. We like to take 1-mm thick samples for a detailed chloride concentration profile as shown here.

On the other hand, if you’re evaluating an existing structure—for example, to estimate its remaining service life—all you need to do is take a core. The sampling and analysis will take only a week or two.

NT Build 492

NT Build 492 uses an electric current to drive the chlorides into the concrete to save time. The time of exposure to chlorides varies between 24 and 96 hours, after which the concrete sample is split open. Spraying an indicator solution of silver nitrate (AgNO3) onto the broken surface shows where the chlorides have penetrated. The depth of penetration is used to calculate the diffusion coefficient.

Choosing between ASTM C1556 and NT Build 492

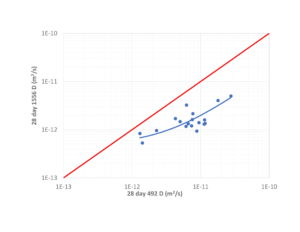

As you can see in the figure, the diffusion coefficient from ASTM C1556 will be somewhat lower (that is, more favorable) than that from NT Build 492.

If you’re using the test to evaluate or compare different concrete mixture proportions for new construction, you’ll need to make and cure the concrete for either test. A 28-day cure is usually sufficient. Once it’s cured, you have a choice between a few days for NT Build 492 and a couple of months for ASTM C1556. Or you can correlate the two values for your concrete and then just use NT Build 492.

However, if you’re evaluating an existing structure, ASTM C1556 is more appropriate. The curing and exposure are already complete, so it’s just a matter of a few days to sample and analyze the concrete.

If you’re placing concrete where it will be subject to more than one exposure class, you need to evaluate it for all of them. For further guidance on choosing the right test, contact us.